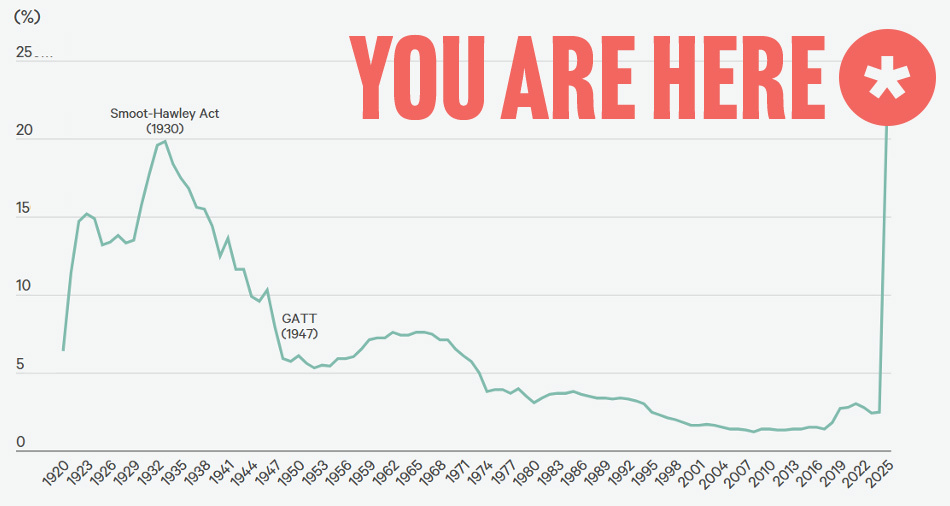

You are here.

"President Trump's announcement of a broad-based global tariff…put the average weighted U.S. tariff higher than at any point in the past 100 years." (Coldwell Banker Richard Ellis, April 2025)

The headlines are real. The labor concerns are real. The cost of construction materials is real. Your concern or anxiety regarding whether to proceed with your ministry's construction project? That's real, too.

In this sort of market, is it responsible—is it part of good stewardship—for a church or other ministry to move forward with its plan to grow? If so, how can unknowns be managed proactively and appropriately?

Great questions. Continue reading for some answers. Hint: there's good news…

Reality check.

If you're looking for data on whether construction material costs are volatile and increasing, you'll find it. The truth is construction costs are going to increase (they always do). The deeper truth? The cost of a project today is going to be less than it will be at this time next year (it always is).

Tariffs, the looming threat of additional tariffs, and any other factor that could cause potential construction cost increases can be mitigated. These are not good reasons to avoid a construction project—especially not when the vision, support, momentum, and timing seem to be right for a church or ministry.

The labor challenge.

The increase of material prices is another ‘usual suspect’ posing a risk to the construction industry. Considering the U.S. imports almost half these materials from Canada, Mexico and China, this is a reasonable concern. There is, however, a more concerning issue: a potentially dwindling U.S. workforce.

More of the labor force is retiring than entering it. “…those retiring are not being readily replaced by the next generation.” (U.S. Chamber of Commerce, June 2025)

The U.S. Bureau of Labor Statistics revealed foreign-born workers comprise 19.2% of the U.S. labor force. That's a significant portion of the workforce, and economic analysts note that changes in immigration policy could impact various sectors that rely heavily on these workers as well.

Same song, different verse.

Whether it's attributed to tariffs, raw material costs, labor shortages, petroleum costs, environmental regulations, or outright price gauging, this volatility is not new. Headlines can easily elicit uncertainty, cold feet, and second-guessing.

There is good news, though. With a strategic approach, most construction projects can continue to move forward in pursuit of the people's vision, and within God's timing. Here's how.

Construction Management 101: 9 Strategies

AGFinancial's construction services team recommends these specific strategies before entering any sort of build contract or construction agreement:

1. Choose your partners wisely

Engage trusted, experienced contractors with excellent reputations and credit relationships. Their suppliers and vendors will work to protect their best customers from price increases, so you as the end user will benefit, too.

2. Lock in your price

Never agree to open-ended contracts or agreements. Ensure there is a "guaranteed maximum price" or "not to exceed" contract amount.

3. Protect against increases

Ensure all contracts and agreements protect both contractor and owner from unforeseen price increases upon execution of the agreement and financial commitment. This may involve additional deposits or down payments to secure materials, so be sure storage is secured (if necessary), and the product is insured through a Builder's Risk Insurance policy.

4. Explore alternatives

Work with your contractor and/or sub-contractors to identify alternate models or brands other than what was specified by the designer, architect or engineer.

5. Order early

Order and secure materials as soon as possible to avoid future volatility.

6. Plan for tariff exposure

If specific materials require importing and expose the contractor to possible tariffs, consider a "Fair Notice Provision" requiring the supplier to notify all parties of the increase. This allows time to adjust budgets accordingly through the use of contingency or cost-reduction in other areas.

7. Share the risk

If the cost increase potential cannot be mitigated, ask the supplier to consider "sharing" the cost, and/or "capping" the cost increase to an agreed amount or percentage. An identified increase is always better than an unknown or unlimited one.

8. Plan for flexibility

Identify project elements that can be delayed to later phases. Set aside 10-12% of total project cost as contingency to cover deferred items and unexpected costs. Reduce this buffer as the project progresses and risks become clearer.

9. Create specific contingencies

Consider a specific line-item contingency for items that cannot include a guaranteed cost or that would be subject to a possible tariff or increase; so the worst-case cost is actually in the contract, but the owner realizes the savings if the cost winds up being less.

You’re not alone.

If that all seems overwhelming, it's ok. Managing construction, its unknowns, and dealing with 'surprises' that may impact your project are very real challenges. Identifying worst-case scenario costs and anticipating those unknowns (as much as possible) are best practices.

In spite of headlines, labor concerns, and construction's inevitable increasing costs, projects in the U.S. are proceeding. Yours can, too.

AGFinancial's construction loan team remains committed to walking with ministries through these challenges. Our priorities are proactive consulting and seeing your project through completion and beyond to ensure the results are best for your ministry.